|

Preparation |

| Home |

| The most common method to prepare polyurethanes is by

reacting a polyol with a di or polyisocyanate. |

R-OH + R1-NCO ® R-OCONH-R1 |

2 R1-NCO + H2O

® R1-NH-COOH

® R1-NHCONH-R1

+ CO2 |

R1-NCO + R-NH2 ®

R1-NHCONH-R |

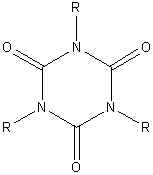

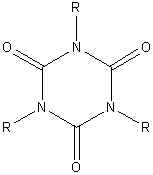

3 R-NCO ® |

|

Isocyanurate ring |

|

| The polyurethanes can be light

stable if the isocyanates used are aliphatic or cycloaliphatic in nature. In addition the

polyol has to be light stable. For lower cost applications or where light stability is not

important aromatic isocyanates can be used. Aromatic isocyanates are faster reacting under

most conditions than aliphatic isocyanates. The urethane linkage is very polar and strongly

hydrogen bonded. This hydrogen bonding leads to an increase in the glass transition

temperature (Tg) of the polymer and to a change in solubility of the polymer. The high

cohesive energy if the urethane groups is 6294 cal/mol or 26370 J/mol. The different

solubility parameter of the urethane linkage leads also to a phase separation and to the

formation of polar hydrogen bonded domains. Polymers high in urethane groups can be

dissolved in solvents also strong in hydrogen bonding capability such as

1-methyl-2-pyrrolidone (CAS # 872-50-4). Crosslinked polymers and foams can be swollen in

this solvent. The reaction of a polyol with an isocyanate requires in most applications

a catalyst. Organotin and

non-tin compounds can

be used for the catalysis of aliphatic and aromatic isocyanates. Aromatic

isocyanates are catalyzed

with t-amines. |

| Urea linkages can be formed by the

reaction of water with isocyanates, as a side reaction also carbon dioxide is

produced. This reaction can be a problem if void a free polyurethanes is to

be prepared. This

reaction can be used to advantage in the preparation of foams. In the

preparation of foams blown with carbon dioxide special

t-amine catalysts are used to achieve the high reaction rate of the

aromatic isocyanate with water. The urea linkages formed

from isocyanates and water is a extremely polar and a strongly hydrogen bonded group. This

group is even more prone to phase separation and to be incompatible with the remaining

polymer. The cohesive energy of the urea group is 10,000 cal/mol or 41,900 J/mol.

Solubility of urea group containing polyurethanes is even poorer than only urethane

containing polymers. The high glass transition temperature of polymers prepared with urea

groups leads to a high heat distortion temperature of polymers. The linkage is also

very stable to hydrolysis under basic and acidic conditions. If the urea groups is formed

from aliphatic isocyanates the polymers are also very light stable. A high content of urea

groups can lead in coatings or moldings to lower gloss. If the formation of urea is a side

-reaction and has not been considered in the molar ratio of polyol to isocyanate it can

lead in low functional polymers to poor resistance properties. Direct

formation of polyureas is also possible by reacting a polyamine with an

isocyanate. The reaction is extremely fast and with primary sterically non-hindered amine

almost explosive. Using sterically hindered amines or amines with a lower pKa value the

reaction speed is more manageable. Because of the high reaction speed the application of

such as system is in plural component spray applications where the components are

mixed in the spray zone. Also RIM (reaction injection molding) compounds can be prepared

by this reaction. Polymers prepared by this reaction have a high heat distortion

temperature. |

| The trimerization of isocyanates in the

presence of certain catalysts

leads to an isocyanurate ring which is a very temperature stable link. This reaction can

be used to create temperature stable polymers with high flame resistance. By combining

conventional polyurethane reaction with isocyanurates flame resistant foams can be

prepared. The heat distortion temperature of polyurethane RIM formulations can also be

improved with isocyanurate crosslinks. |

| The reaction rate of a polyol with an isocyanate is very slow in the

absence of a catalyst. Many compounds can catalyze the reaction of an isocyanate with a

polyol. Typically in polyurethane systems, dialkyltin,

lead octoate, zinc octoate and

amines are used. For aromatic isocyanates amines are very effective catalysts. Dibutyltin

dilaurate (DBTDL) is a standard catalyst for aliphatic and cycloaliphatic isocyanates.

Catalysts which catalyze the hydroxyl reaction also catalyze the water reaction. DBTDL

shows some preference for the hydroxyl over the water reaction. Amines on the other hand

preferentially catalyze the water over the hydroxyl reaction. |

|

|

|

|

Last edited on:

|

November 14, 2006

|

Copyright®, Design, Layout and Technical Content by:

|

|

|

|